The business value of sustainability is well-known today. The value of a circular economy though is perhaps less known and certainly less understood. Moving towards a circular model can help businesses build resilience against the volatility of raw material prices, supply chain risks, and changing legislation.

The aim of the game is to move away from a linear economy to a circular one that ‘designs out’ waste and pollution – keeping materials in continuous circulation. A circular economy is designed to be restorative and regenerative. Following the strategic framework for a circular economy forces you to consider not just the impact of the product itself, but also

- the service it provides

- the supply chain that enables that service, and

- the broader economic, environmental, and social impacts of the whole system.

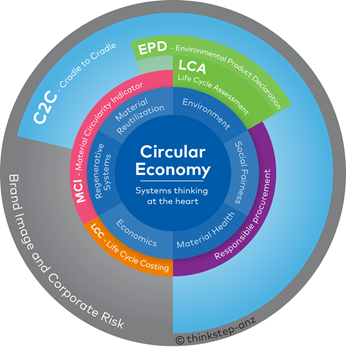

Transforming the concept of circular economy into action can be achieved with help of circularity tools such as the Material Circularity Indicator (MCI), and complementary life cycle based approaches, including:

- Life Cycle Assessments (LCA)

- Cradle to Cradle (C2C)

- Environmental Product Declarations (EPDs).

There are many tools and approaches to assess the sustainability of your products – it can be overwhelming to know where to start. The good news is that many of the methods and tools are related and often inform each other.

Fit for purpose – strategy first

Before you engage with any of these methods or tools, it’s important to set out your objectives and have a sustainability strategy in place. Understanding what is important to your business and your stakeholders is critical. You also need to think about what sustainability issues might affect your business and what your greatest risks are. This will help you build a roadmap with actionable and manageable steps.

Even if you have similar ambitions to other companies, your roadmap and action plan will probably look very different. The life cycle approach to sustainability is great for informing strategy and design briefs.

Applying life cycle thinking

Life cycle thinking is a holistic way of looking at the whole life cycle and value chain of a product – from the extraction of raw materials and processing, through to product manufacture, delivery, use, and finally to waste management and recycling.

Like the circular economy, it is based on a ‘systems thinking’ perspective that involves looking at a product as part of a system, which also includes the service associated with it.

Examining each stage within the life cycle of your product means that you can identify where you can make the most positive impact: environmentally, socially, and economically. It also reveals whether you are burden-shifting. This is when you make a positive impact at one stage of the life cycle but unintentionally create problems at another.

Quantifying life cycle impacts with LCA

Once you have a better understanding of your entire life cycle, you can choose to undertake a Life Cycle Assessment (LCA). This is a great way to quantify the environmental impact of your product at each stage over its entire life cycle using a wide range of indicators, such as carbon footprint, energy use, and water consumption.

An LCA provides insights on your products or services that allow you to make decisions based on science-based environmental data. If you want to compare products with LCA, you’ll need to get it peer reviewed by three independent experts to make sure it meets the standards.

LCA reports are in-depth and technical. If your audience requires a more reader-friendly document, you could consider publishing an Environmental Product Declaration (EPD) instead or alongside the report. An EPD is based on your LCA but is condensed down to a document that aims for full transparency and integrity for its reader. It must be verified by a third party. It follows a specific set of rules for different product categories. This allows you to make comparisons with data-driven information. An EPD is often likened to a nutrition label — it presents the environmental information in a way that is easily accessible and comparable without attributing a positive or negative value to the product.

Measure and improve the circularity of a product with MCI

Where LCA focuses on understanding the impact of materials through indicators, the Material Circularity Indicator (MCI) looks at the circularity of the materials. This tool is the brainchild of Jim Goddin and the Ellen MacArthur Foundation, one of the leading institutes advocating the circular economy.

The MCI addresses a challenge that manufacturers often face with the circular economy – measuring the circularity of their products. Using the MCI leads to a score card for materials ranging from 0 (for a linear system) and 1 (for a perfectly circular system). The MCI tool translates the circular economy from a high-level concept into one that enables tangible action.

The MCI looks at the circularity of materials, which is part of the circular economy but not the whole circular economy. You can greatly reduce your carbon footprint yet operate within a linear system. Likewise, you can achieve a perfect MCI score but still hurt other aspects of the environment. A multi-pronged approach combining these tools will allow you to achieve your circular and wider environmental ambitions. The circularity information in an MCI can be combined with the wider environmental data of an LCA study through EPDs.

InfraBuild was the first company in Australasia to incorporate the MCI into their EPDs. While this provides them with a bigger picture of environmental outcomes, a full picture is not possible without looking at the social impact. This is where Cradle to Cradle (C2C), the ultimate product certification comes in.

The ultimate sustainability certification — C2C

Image source: EPEA

Where many companies and initiatives focus on doing 'less bad', Cradle to Cradle is all about doing 'more good' and designing products that are good for the world.

Like the MCI, C2C looks at the circularity of materials, trying to ensure all materials become nutrients again for either a natural or a technical process – ‘growing’ the next product. But C2C goes a step further and pulls in other influential factors to achieve a true circular economy – one that does right for the economy, environment, and society.

A C2C certification is the optimal sustainability certification. It assesses your products against indicators for material health, material reuse, renewable energy and carbon management, water stewardship, and social fairness.

C2C will help you contextualise all circular economy aspects and is a great way to verify if the objectives of a circular economy have been considered holistically and to their broadest extent.

Working together to achieve a truly circular economy

When combined, LCA, MCI, EPDs, and C2C help to achieve a truly circular economy that incorporates social, environmental, and economic dimensions. From a business perspective, they also help to create products that will perform better in a market that is increasingly connected to social and environmental performance.

By Barbara Nebel and Caroline Noordijk

This article was first published in NZ Manufacturer magazine, April 2021.