The newly released ISO standards for circular economy provide clear guidance on transforming your business model – and avoiding greenwashing

As sustainability becomes a central focus in global markets, understanding and adopting the ISO 59000 series standards will help manufacturers stay competitive, reduce waste, and align with global sustainability expectations.

Why circular economy matters for manufacturing

Manufacturing relies on many unique resources. New Zealand’s MBIE published in September its draft list of critical minerals for consultation. It comprises 35 minerals that it considers essential for many applications across the New Zealand economy, including healthcare, agriculture, electronics, transport, and construction. These minerals are vital for the low-carbon technologies we need and underpin most of our manufacturing value. They are also subject to supply disruptions resulting from monopolistic supply chains, resource nationalism, conflict and climate change impacts.

We need to become better stewards of these materials and prevent them from being wasted. The circular economy offers a solution by promoting the more efficient use of resources, reducing waste, and encouraging innovative approaches to design, production, procurement and use.

Extending the service life of products and reusing critical components enables valuable resources to be recovered, lowering costs and creating opportunities for new businesses linked to recovery and remanufacturing.

More than recycling

While recycling undoubtedly has a role, many critical minerals are lost or diluted through the recycling process. The supply chains that turn recycled materials back into products are often offshore.

The Intergovernmental Panel on Climate Change estimates that about half of the environmental problems we need to solve are linked to how we make and use products while the other half comes from the types of energy we use.

![]()

Avoiding greenwashing with ISO Standards

Greenwashing happens when companies make false or exaggerated claims about their environmental efforts. This is a growing concern as consumers become more environmentally conscious. The ISO standards help you avoid greenwashing by providing a clear, verifiable framework for circular practices.

For example, ISO 59020 requires manufacturers to measure their resource flows and recycling rates, ensuring that their "sustainable" or "circular" claims are based on solid evidence. This helps build trust with consumers and regulators and protects businesses from accusations of greenwashing.

![]()

Why businesses should adopt these standards

- Staying competitive globally: The ISO standards are recognised internationally, giving you an edge when exporting products to markets where consumers demand circular and sustainable solutions. Having robust, traceable data on sustainability or circularity claims will soon be a legal requirement for placing products on the EU market under the Ecodesign for Sustainable Products Regulation (ESPR) that has just come into force.

- Meeting regulations and reducing risk: Environmental regulations are becoming stricter worldwide. The ISO standards can help you to align with these regulations, reducing the risk of fines and legal challenges. By adopting these practices early, you can stay ahead of regulatory changes and avoid potential disruptions.

- Driving sustainable growth: Circular economy practices can create new opportunities for growth. By rethinking how products are made, used, and reused, you can lower costs, explore new business models like leasing or product-as-a-service, and tap into new markets.

- Innovation and collaboration: The ISO standards emphasise working together across industries to achieve circularity. New Zealand manufacturers can collaborate with others to find new ways to reuse materials, redesign products, and close the loop in production processes.

What are the ISO 59000 standards?

The ISO 59000 series provides a framework to help businesses adopt circular economy principles. These standards are particularly relevant to manufacturers and offer a step-by-step approach to transitioning to more sustainable practices. Here’s a quick overview:

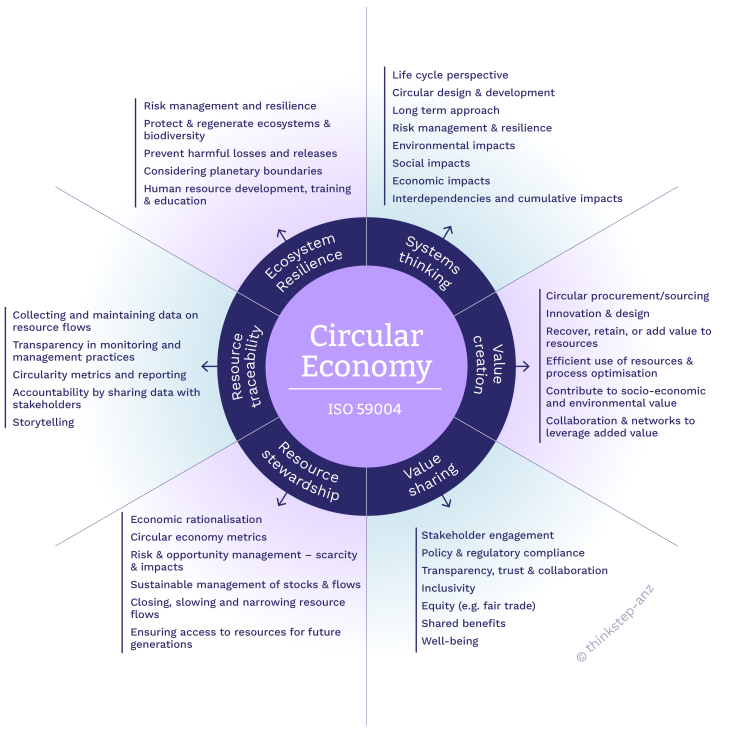

ISO 59004: Defining the circular economy

ISO 59004 sets the foundation for the circular economy, providing clear definitions and principles. This helps businesses speak the same language when discussing circularity. It encourages you to think about how you can reduce waste and improve resource efficiency at every stage of your production

ISO 59010: How to transition to a circular economy

This standard provides guidance on how you can shift from a linear model (using resources once and then discarding them) to a circular one. It helps you to set goals, plan strategies, and make changes to your operations to reduce waste and improve resource reuse. Importantly it starts from the economic rationale behind the transition, enabling you to develop a sound business case.

ISO 59020: Measuring Circularity

One challenge businesses face when adopting circular economy practices is knowing how to measure their success. ISO 59020 gives you the metrics to benchmark your performance and track your progress. Importantly, it looks beyond recycling and enables other circular strategies, such as durability, reuse, remanufacturing, and nature-based solutions, to be compared on an equal footing.